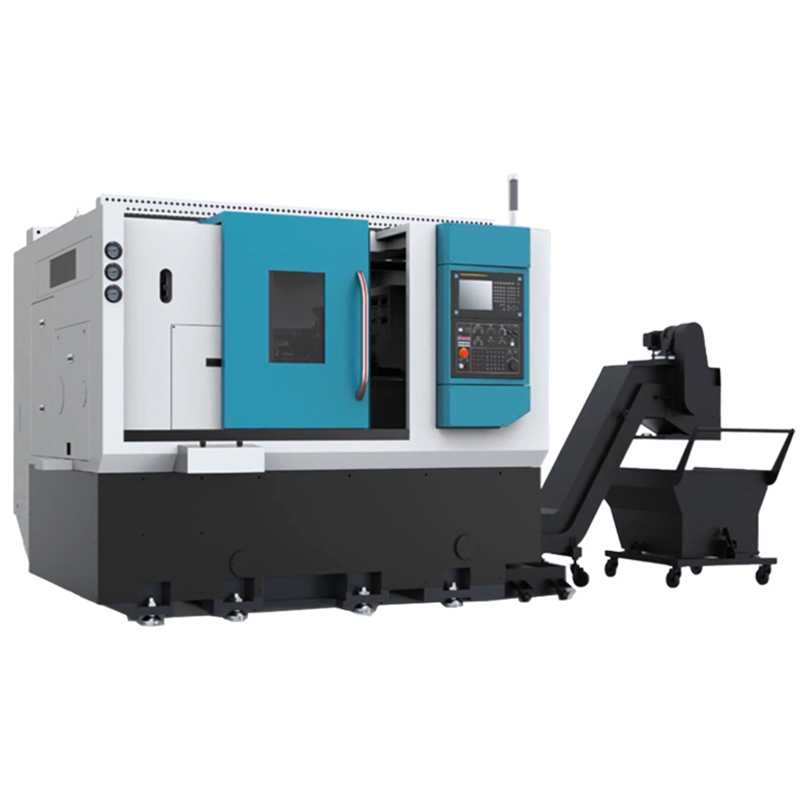

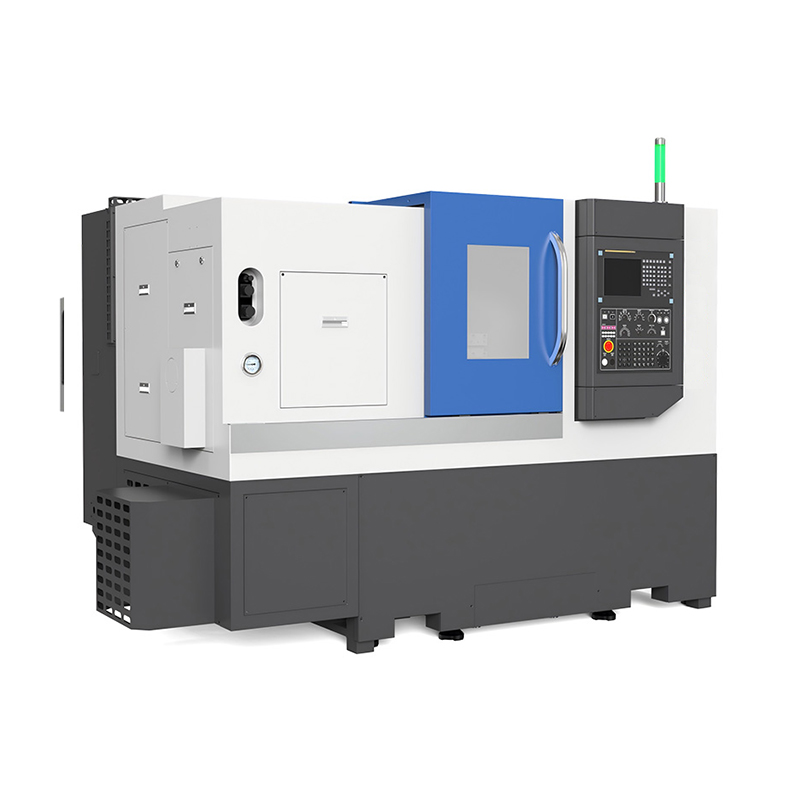

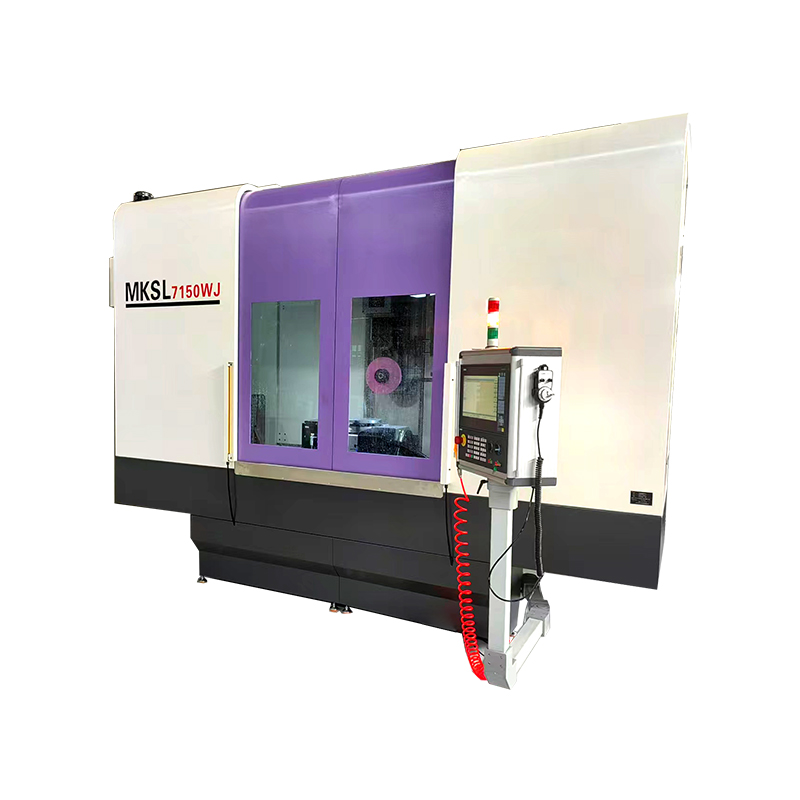

L-46SDY Horizontal Twin Spindle Twin Turret CNC Lathe(Turning-Milling Center)

Complete Machining in One Setup: The L-46SDY Twin Spindle CNC Turning-Milling Center for Precision Production

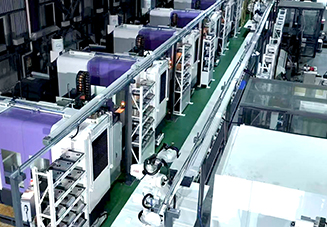

The L-46SDY twin spindle twin turret CNC machining center redefines manufacturing efficiency with its fully integrated design. By combining dual-spindle synchronized transfer and 3D motion dual Y-axis turrets, this CNC turning-milling machine consolidates multiple standalone operations from turning and milling to drilling, boring, and tapping into a single, continuous workflow. Unlike traditional multi-machine processes, the L-46SDY eliminates inefficiencies, setup repetition, and production bottlenecks, transforming your shop floor from fragmented process flow into seamless process integration. This all-in-one horizontal machining center delivers complete part finishing in one chucking, enabling true single-machine workshop capability for batch production of precision components.

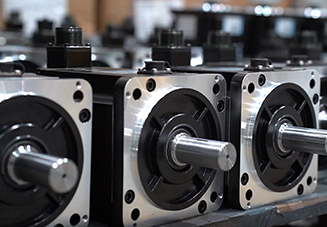

Twin Spindle Synchronized Machining– enables automated loading and unloading

Dual Y-Axis Turret Design– equipped with 12 station BMT45 servo tool holder

Maximum Machining Diameter Φ570mm, Maximum Turning Length 130mm

Complete machining operations—including turning, milling, drilling, and other processes—in a single setup.