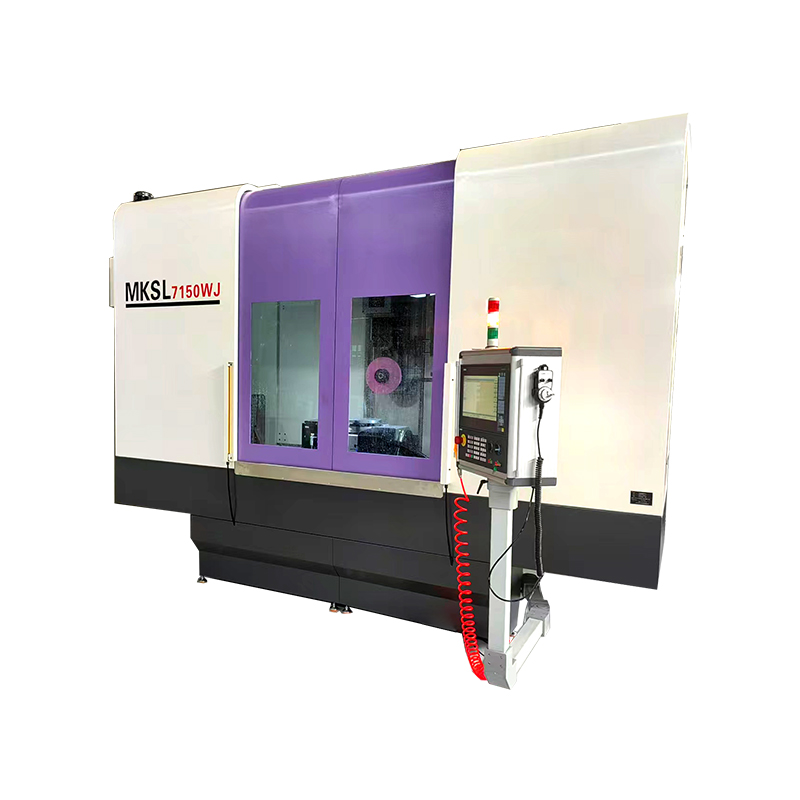

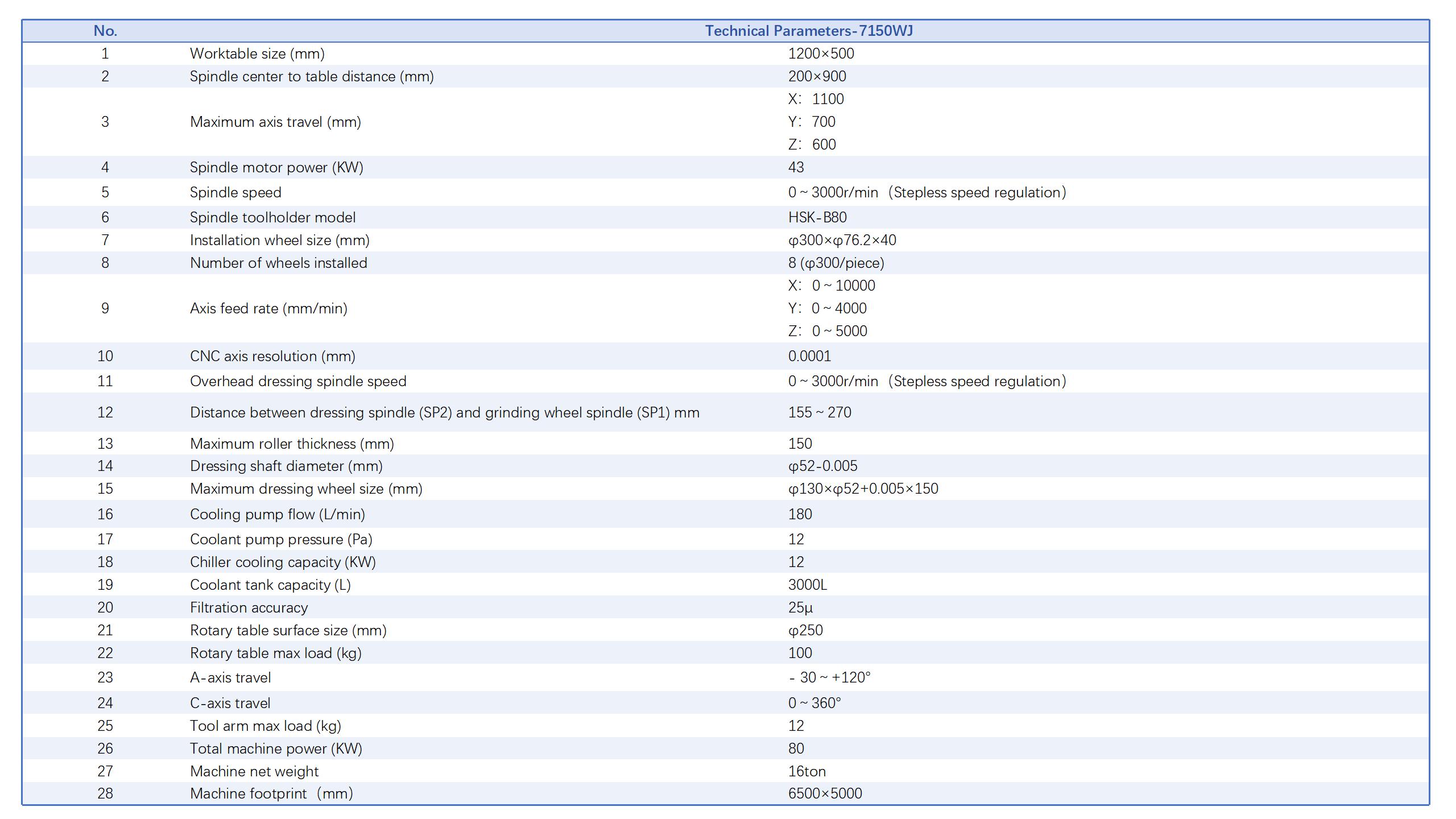

MKSL7150WJ High-Performance 5-Axis CNC Creep-Feed Grinding Center is specially designed for high-precision and complex surface grinding, particularly suited for precision manufacturing of difficult-to-machine materials in aerospace and other demanding industries. | SPECIFICATIONS: √ 5-axis simultaneous motion (X, Y, Z, C, U1) √ Wide table feed range (30–10000 mm/min) √ Integrated overhead wheel dressing system √ Capable of holding 8 different wheel profiles simultaneously, with automatic tool changing function. √ Equipped with Siemens 840DSL CNC system

The MKSL7150WJ is a high-performance CNC creep-feed grinding center integrating five-axis simultaneous motion, intelligent wheel dressing, and automatic tool changing capabilities. Widely used in the aerospace and energy equipment industries, the MKSL7150WJ is an ideal solution for manufacturing critical components such as turbine blades, guide vanes, and compressor blades, as well as for batch and flexible production of high-precision, hard-to-cut workpieces.

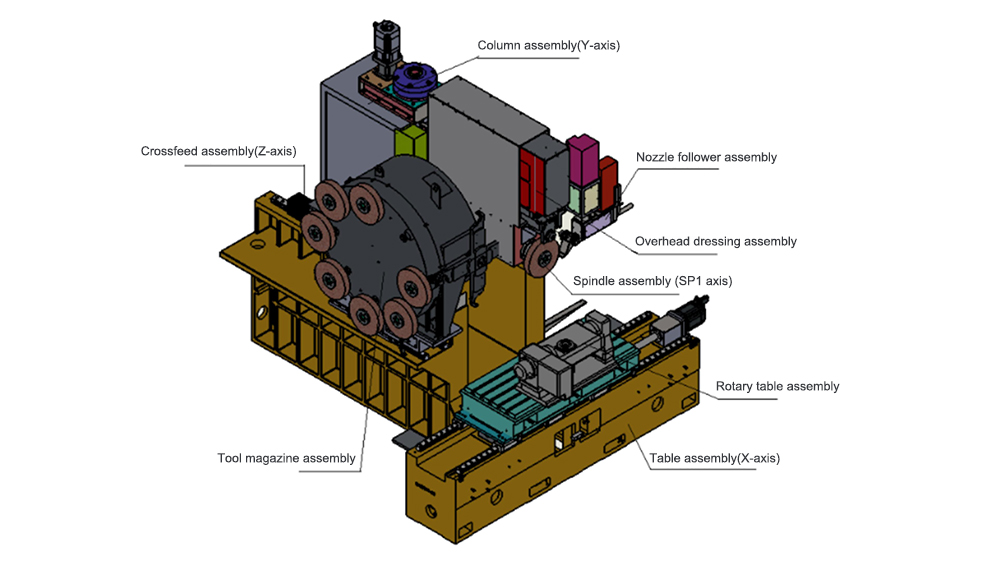

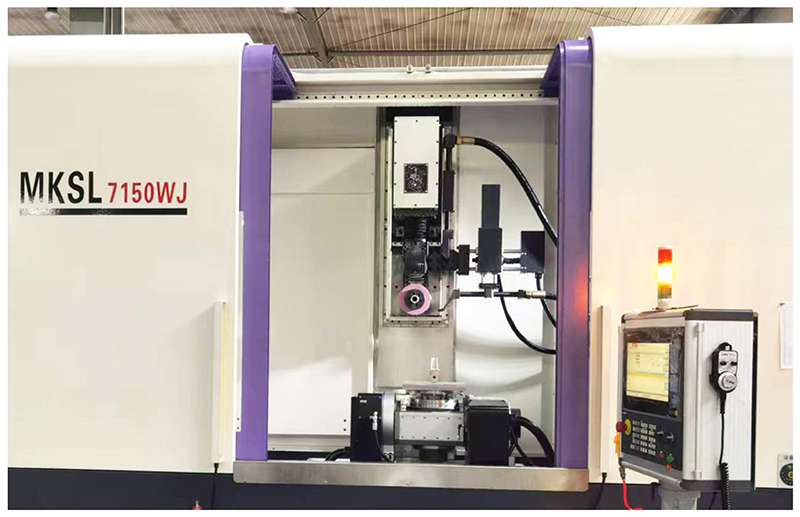

The machine is comprised of the following main components: Main unit (X, Y, Z axes and spindle assembly), Wheel dressing system,Cooling and filtration system, Protection system (machine enclosure, lubrication system, pneumatic system, mist • extraction system), Nozzle following system, Wheel magazine and automatic changing system, Rotary table system, CNC control system.

| The grinding spindle is driven by a high-power Siemens servo motor and features an ultra-precision bearing structure with support at both ends. The bearings are protected by a triple-seal design incorporating mechanical labyrinths, lip seals, and air seals, effectively isolating coolant and grinding debris to ensure high reliability, extended service life, and stable precision. The spindle front end is equipped with an SHK-B80 tool holder interface and a hydraulic tool clamping mechanism, providing a consistent drawbar force of 1800 ±50 kgf. Lubricated with maintenance-free grease, the spindle system offers robust construction and simplified upkeep. |  |

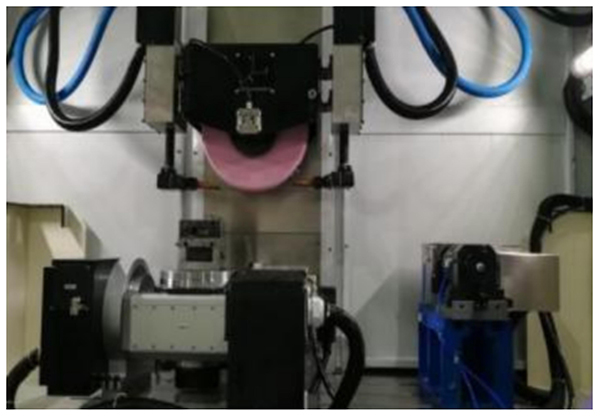

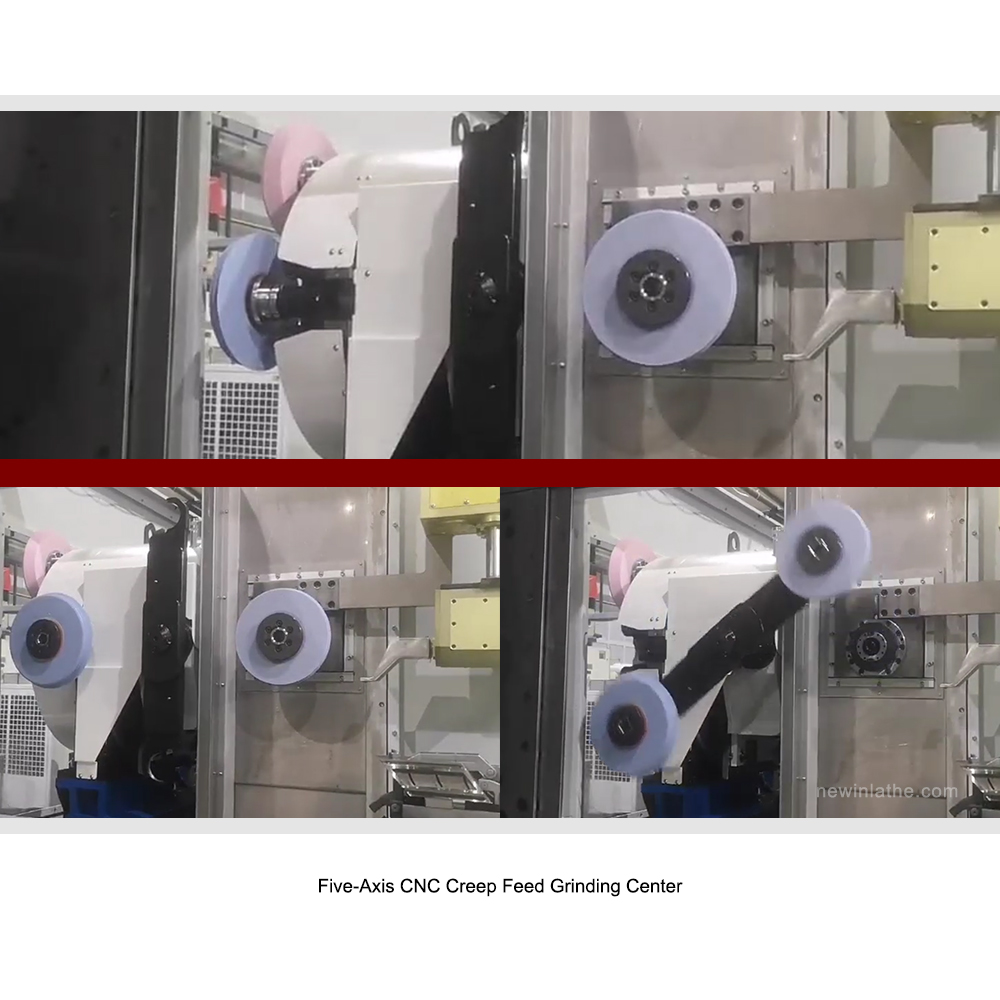

| • Overhead Dressing System with Independent Two-Axis Linkage The overhead dresser is integrated into the spindle housing and moves synchronously with the spindle in the Y and Z axes. Its independent SP2 dressing axis features dual-axis adjustment capability along U1 (vertical lift) and U2 (front–back movement), enabling flexible positioning to achieve efficient and precise dressing of multiple wheels stored in the wheel magazine, regardless of their mounting positions. • Intelligent Coolant Nozzle Following System The system utilizes dual CNC-controlled axes to drive the coolant nozzle, enabling it to automatically track the grinding wheel along the X and Y directions. During arc grinding operations, the nozzle moves in synchronized interpolation with the wheel, continuously following the grinding point in real time. This ensures precise cooling and effectively prevents workpiece burn. |

| The machine is equipped with a high-capacity wheel magazine and an automatic wheel changing device capable of storing up to 8 grinding wheels with a diameter of φ300 mm, each fitted with a standard HSK-B80 tool holder (wheel flange bore φ76.2 mm). All wheel-changing operations are executed through automated program control, and the system supports program pre-reading functionality. This enables the next required wheel to be prepared in advance during the machining process, ensuring seamless integration between machining and wheel-changing cycles. As a result, the system significantly enhances continuous operational efficiency and automation levels. |  |

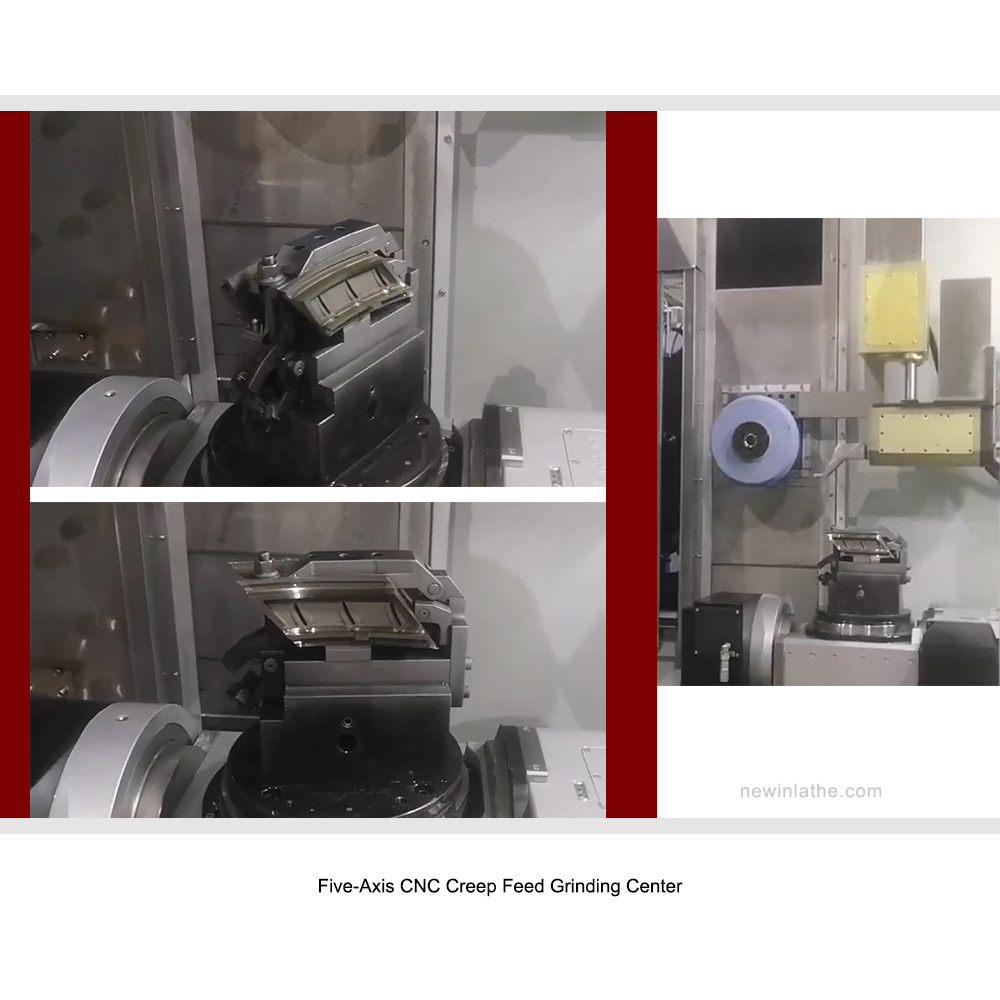

| The machine is equipped with CNC rotary tables (A-axis and C-axis) of a Taiwan-based brand (customizable as per client specifications). Each table integrates a main rotary body, Siemens servo motor, absolute rotary encoder, and motor protective cover. The system provides precise indexing and continuous rotation capabilities, with reliable signal transmission, meeting the process requirements for complex multi-angle precision grinding operations. |

| The machine adopts the Siemens 840DSL CNC system, integrating 8 linear servo axes (X/Y/Z/U1/U2/Q/V/W), 2 rotary servo axes (SP1/SP2), and 2 rotary table servo axes (A/C), supporting five-axis simultaneous motion (X, Y, Z, C, U1). The system features the following: • All axes are driven by Siemens AC servo motors, equipped with an electronic manual control panel and a swivel-type pendant operation panel. • It includes a 15‑inch color display and a Windows‑7 Chinese operating interface, supporting remote services, fault diagnostics, and high‑precision contour control. • Built‑in proprietary five‑axis grinding software package provides parametric programming modules, enabling functions such as wheel dressing, linear/arc/surface grinding, along with process visualization and parameter error alarms. • The system integrates fault diagnosis, electrical cabinet temperature‑control protection, and stabilized power filtering. It is equipped with USB 2.0 and Ethernet interfaces, and supports expansion of production‑line communication data interfaces. |  |

| • Cooling and Filtration System: Equipped with a drum-type filtration unit that integrates paper filtration and scraper chip removal. A 12kW constant-temperature chiller ensures stable coolant temperature and high-precision filtration, guaranteeing process stability. • Lubrication System: Features a PLC-controlled automatic lubrication system for scheduled lubrication of guideways and ball screws. It includes fault alarm functionality for long-term, maintenance-free operation. • Pneumatic Unit: Employs compressed air seals for both the main spindle bearings and the overhead dresser spindle bearings. Cylinders are used for actions such as tool magazine clamping/releasing, protective door operation, and tool magazine door control. The system utilizes clean, dry, and pressure-adjustable air sources. • Protective Enclosure System: Utilizes a fully enclosed metal protective cover structure. It integrates LED lighting, automatic door opening/closing, photoelectric safety sensors, and a smoke collection and exhaust system, offering high safety, effective sealing, and operational convenience. |

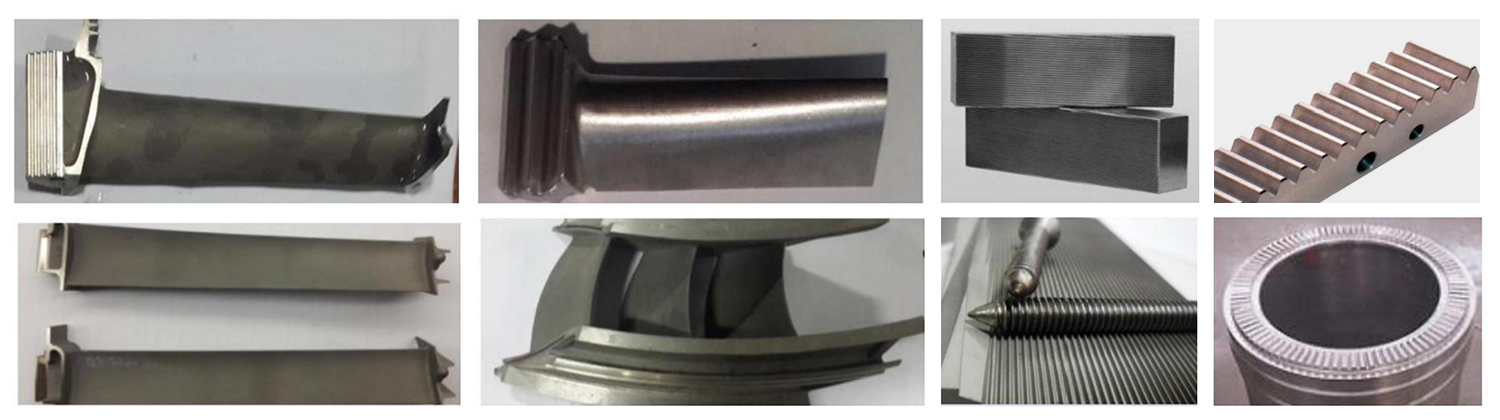

This machine is suitable for high-precision and high-efficiency form grinding of difficult-to-cut materials, complex high-precision surfaces, and special process structures across various fields.

It is particularly well-suited for the precision grinding of complex contours in components such as:

The machine is also designed for large-allowance creep-feed grinding of hard-to-machine materials, including high-temperature alloys.

Contact us for detailed configurations or custom grinding solutions.

Contact us for detailed configurations or custom grinding solutions.