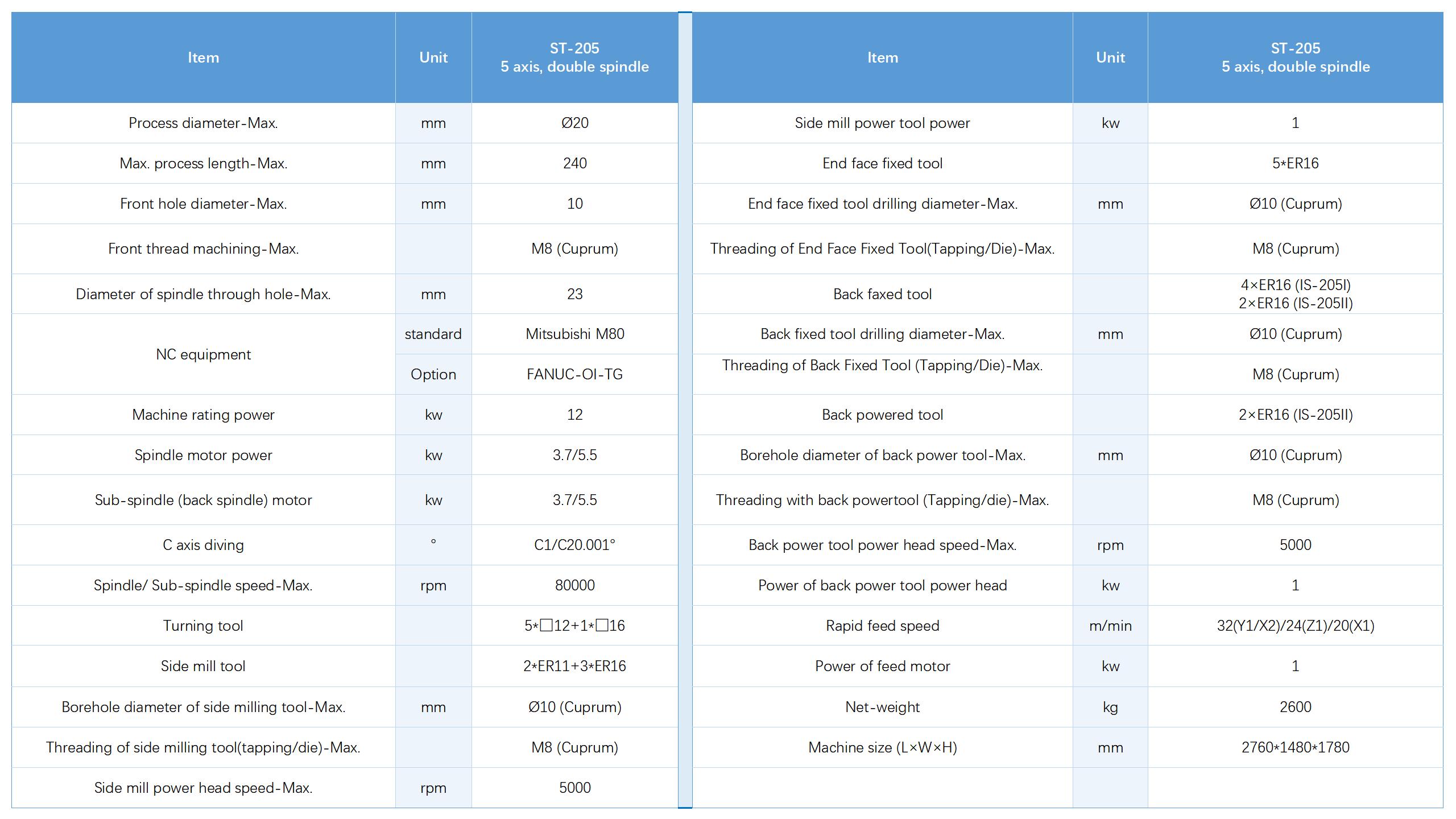

The ST-205 is a high-precision CNC Swiss-type automatic lathe engineered for the high-volume production of precision shafts and complex, non-standard components. | SPECIFICATIONS: √ Dual-Spindle(motorized spindles), Dual-System Turn-Mill Center √ Mitsubishi M80, retrofitted with an Enhanced Thermal Compensation Interface √ Up to ø20mm bar capacity √ Switchable Guide Bushing System √ Cut-Off Tool Detection √ Complete Machining Capability in a single setup, reducing lead times and improving part consistency.

The ST-205 high-precision CNC Swiss-type lathe (Sliding Head Machine) is an advanced solution in the field of precision shaft machining. It is more than just a lathe—it is a multi-tasking turn-mill center that integrates turning, milling, drilling, and tapping operations. By enabling complete machining in a single setup, it effectively eliminates errors from repeated fixturing, delivers consistent high precision, and provides a solid foundation for automated and lights-out production. It is a dependable choice for manufacturing environments that demand both high efficiency and high accuracy.

Equipped with dual independent spindles (built-in motorized spindles) and CNC systems for automatic part transfer and continuous, unattended operation.

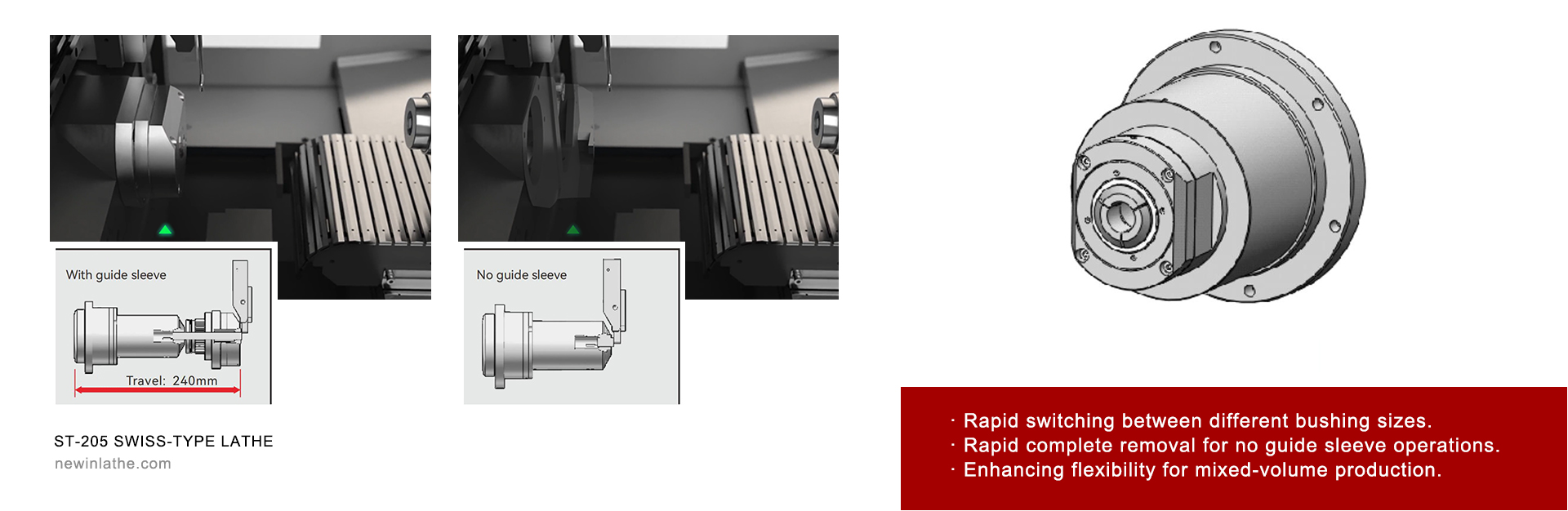

Capable of handling bar stock up to ø20mm (stainless steel) with a maximum machining length of 240mm.

Supporting both rotating guide sleeve machining for supreme precision in turning, and no guide sleeve operation to unlock full potential for complex milling and drilling. This flexibility accommodates a wide range of part geometries.

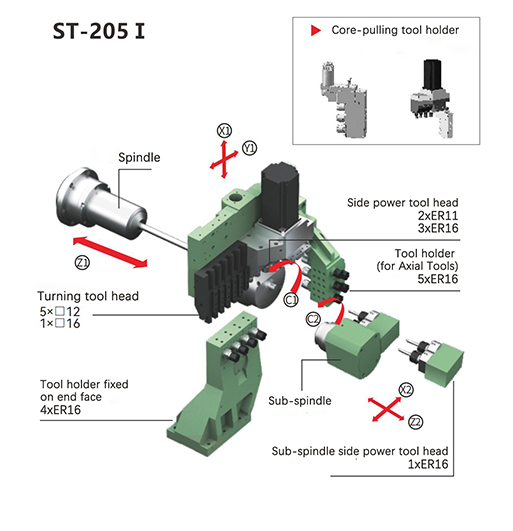

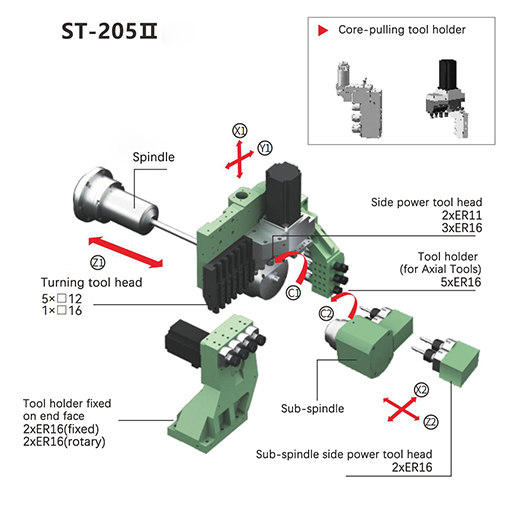

Optimized Tool Layout & Versatility: A rationally planned tool layout, combined with a comprehensive variety of tooling, meets diverse machining requirements.

| Tooling System Decription | |

|---|---|

| Integrated Cut-off Tool Detection & Specialized Tool Holders - Equipped with cut-off tool detection. - Features core-pulling tool holders. - Side Power Tools: 5 units (2×ER11 collet, 3×ER16 collet) - Face Power Tools: 5 units (ER16 collet) High-Performance Milling Capability: - Side and face milling tool heads with power up to 1000W, enhancing milling rigidity and extending tool life. | Flexible End-Face Rotary Tool Holder: - 4 ER16 collets on a rotary holder, optionally selectable for fixed or rotating operation. Back-Spindle Deep-Hole Drilling: - 2 ER16 collets on the sub-spindle side, capable of deep-hole drilling up to 150 mm in depth. |

| Tool Layout IS-205Ⅰ | Tool Layout IS-205Ⅱ |

|  |

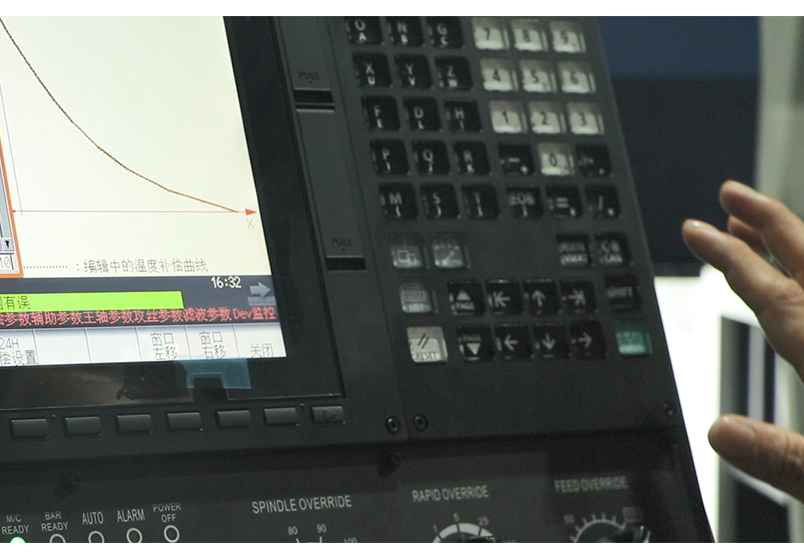

| Premium Control & Precision | |

|---|---|

| Powered by the industry-leading Mitsubishi M80 CNC system with advanced thermal displacement compensation, delivering exceptional speed, accuracy, and long-term machining stability. |  |

| Standard configuration | Optional Configuration |

|---|---|

| • Mitsubishi M80 CNC System • Parts Collection Bin • Cut-off Tool Inspection System • Combined Short/Long Part Catcher • Rotating Guide Bush (Guide Bushless optional) | • FANUC Oi-TF CNC System • Spindle-Nose End Milling Attachment • High-Pressure Coolant Pump / Oil Mist Collector • Power Tool Holders • Automatic Loader |

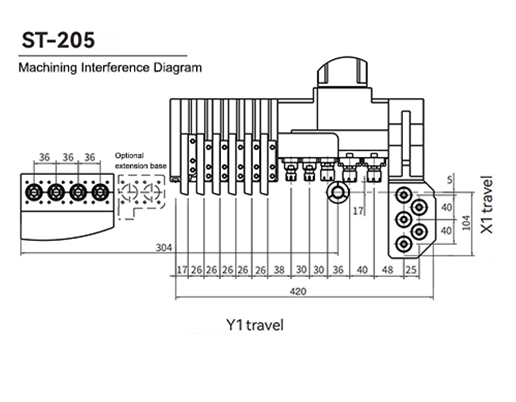

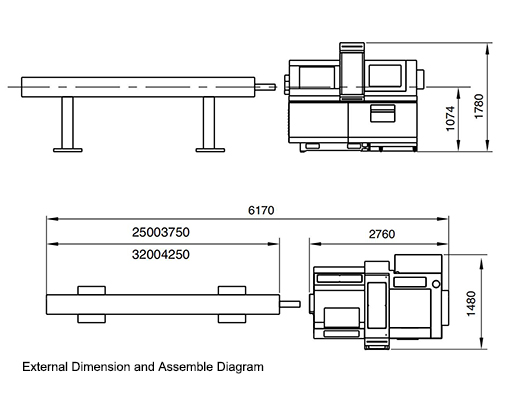

| Machining Interference Diagram | External Dimension & Assemble Diagram |

|---|---|

|  |

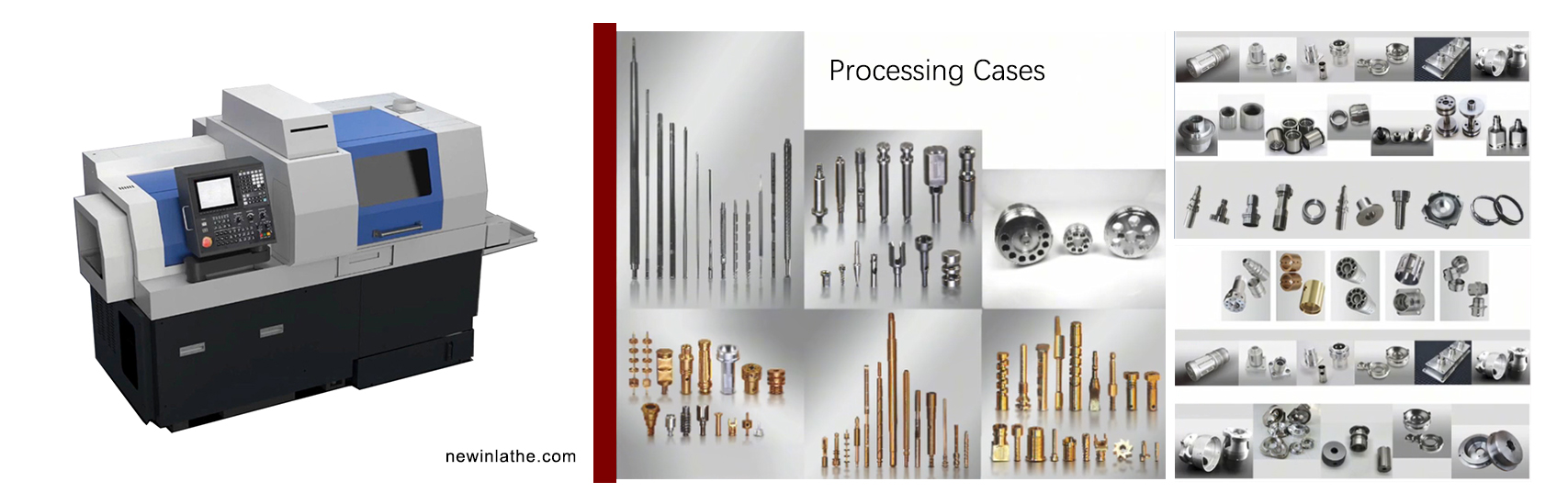

| | Ideal for manufacturing critical components in: |

|---|

| • New Energy Vehicles (motor shafts, sensor housings) • Aerospace & Aviation (miniature fasteners, probe fittings) • Precision Engineering & Electronics (connectors, pins, drive shafts) • Medical Devices (surgical instrument parts, bone screws) • Optics & Instrumentation (lens barrels, adjustment screws) |