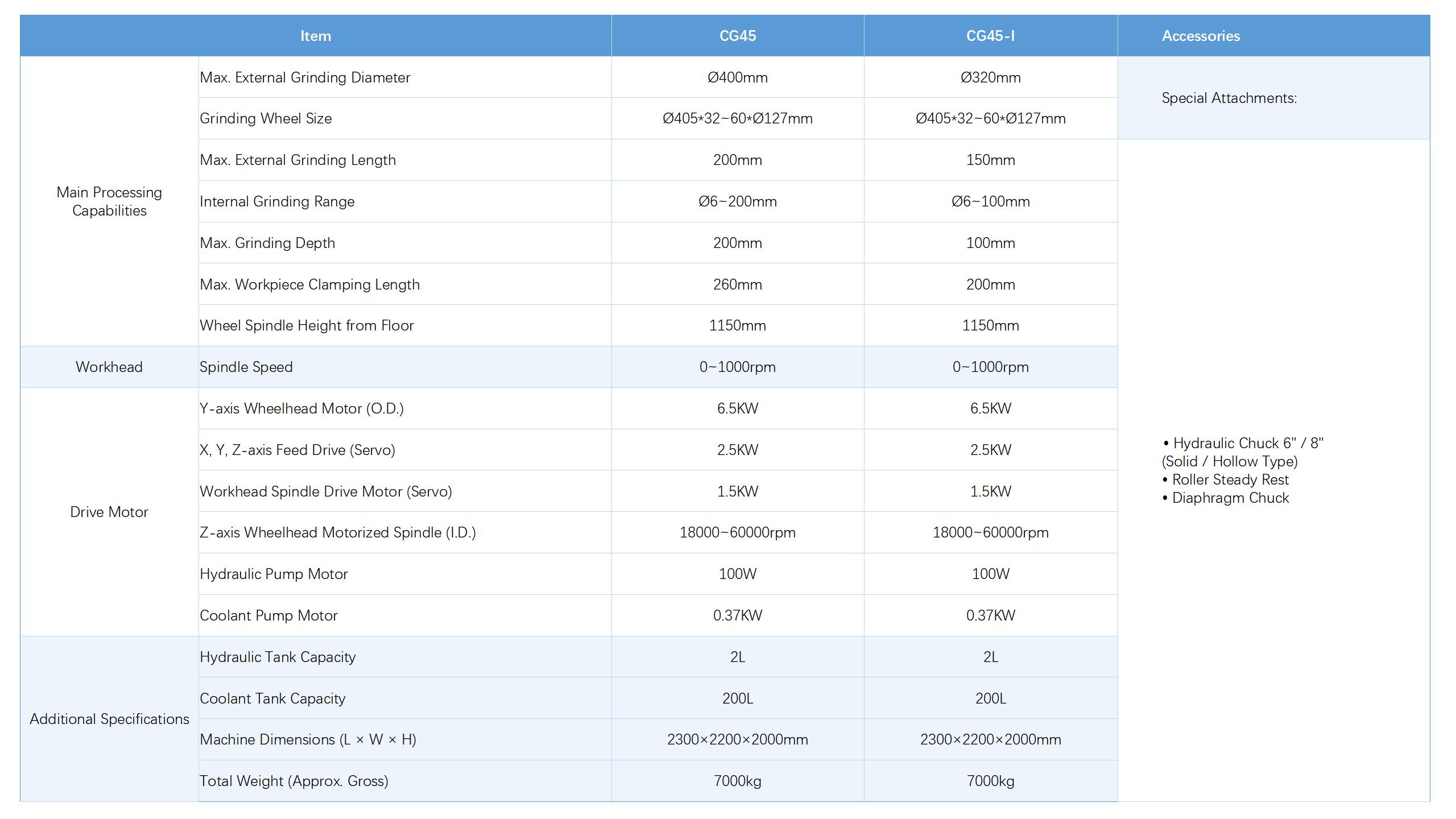

The CG45 high precision multi-function grinding machine combines internal, external, face, and taper grinding in one setup with modular design. | SPECIFICATIONS: √ Internal wheel spindle stroke 0-470mm, External wheel spindle stroke 0-365mm. √ Ideal for high-precision, complex grinding of small to medium parts, with options for automation and in-process gauging.

The CG45 High Precision Multi-Function Grinding Machine is engineered for high-precision, complex grinding applications. Its modular architecture integrates internal, external, taper, and face grinding operations into a single setup, eliminating repositioning errors and maximizing efficiency.

Designed for flexibility, it supports various wheelhead configurations and automation options, delivering a complete grinding solution for small to medium-sized workpieces, from prototyping to high-volume production.

• Perform internal, external, face, and taper grinding without rechucking, ensuring superior concentricity and accuracy.

• Internal Wheel Spindle Stroke: 0 – 470 mm;External Wheel Spindle Stroke: 0 – 365 mm.

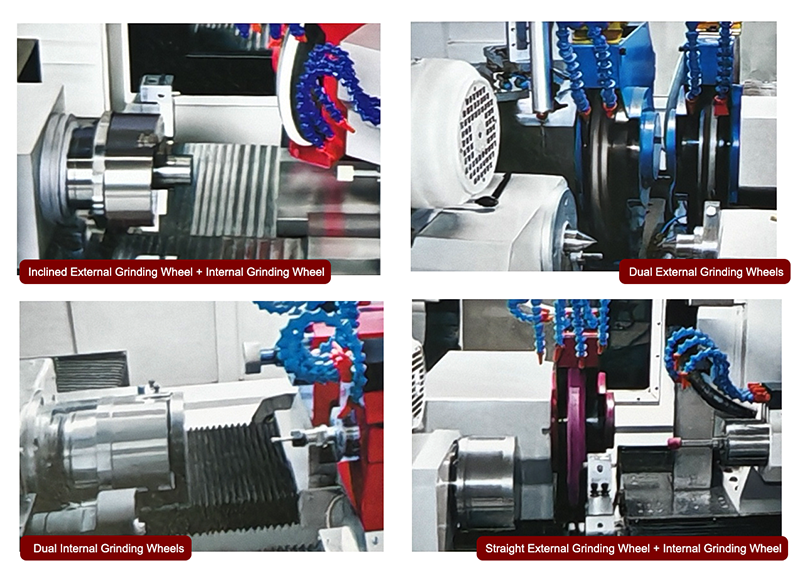

| • Interchangeable Wheelhead Options: > Inclined External Grinding Wheel + Internal Grinding Wheel > Dual External Grinding Wheels > Dual Internal Grinding Wheels > Straight External Grinding Wheel + Internal Grinding Wheel • Mix and match internal/external modules to suit specific part geometries and processes. |

| • Intuitive CNC system allows easy on-machine programming for grinding and wheel dressing cycles. • Compatible with in-process gauging systems for real-time SPC and closed-loop feedback. • Optional automatic loading/unloading systems enable lights-out production for batch manufacturing. |  |

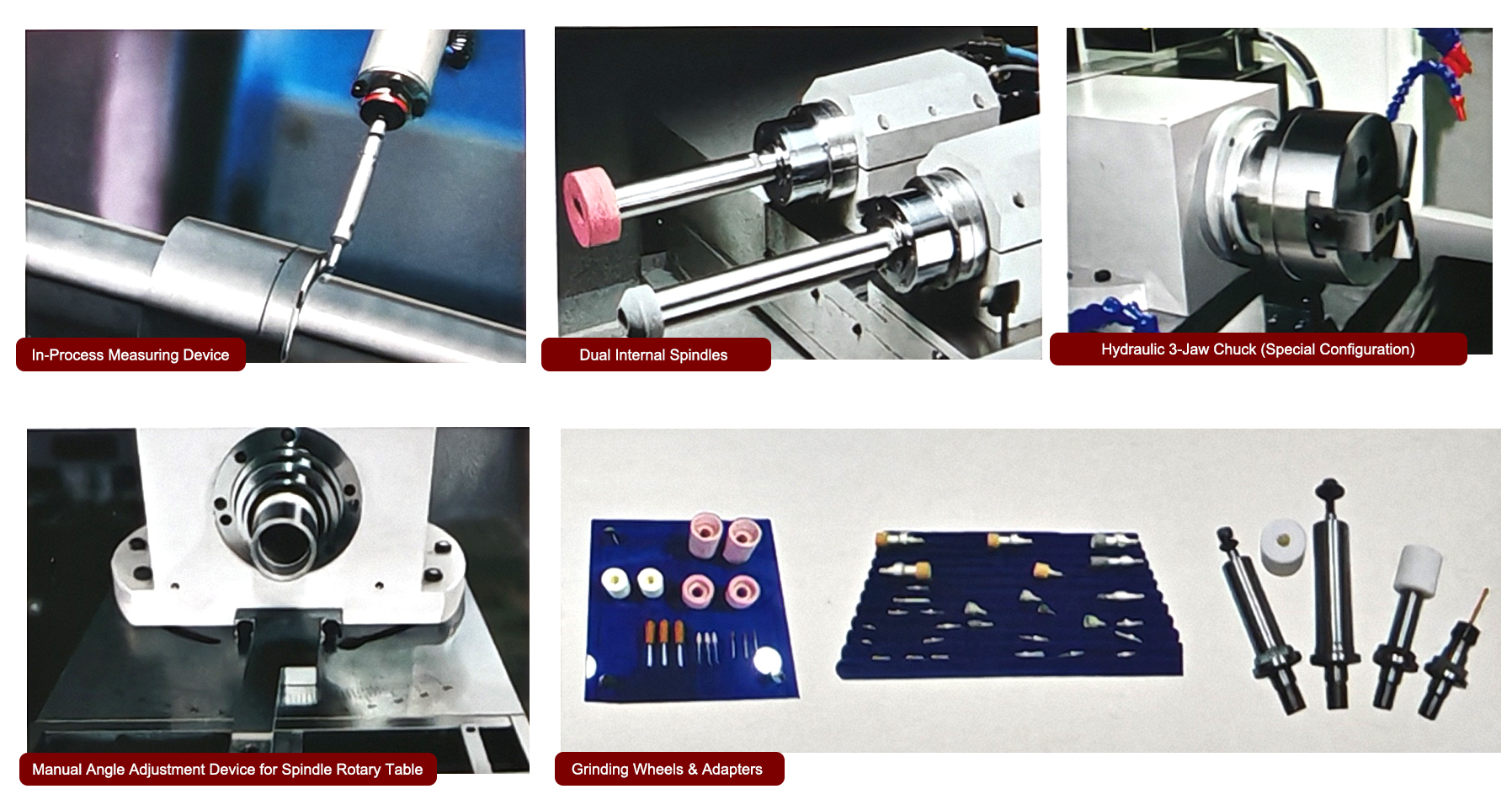

| • In-Process Measuring Device • Dual Internal Spindles • Hydraulic 3-Jaw Chuck (Special Configuration) • Manual Angle Adjustment Device for Spindle Rotary Table • Grinding Wheels & Adapters |

| • Precision Components: Bearings, bushings, mold cores, precision shafts | • Hydraulic & Pneumatic Parts: Cylinder tubes, valve spools, sleeves |

| • Automotive: Transmission shafts, steering components, engine parts | • Tool Manufacturing: Drill bits, reamers, taps (taper & O.D./I.D. grinding) |

Contact us for detailed configurations or custom grinding solutions.

Contact us for detailed configurations or custom grinding solutions.

Shenzhen Newin Intelligent equipment Co., Ltd. focuses on providing customers with cost-effective precision manufacturing lathe solutions. Our products mainly include CNC walking machines, turret/row lathes, turning milling composite, slow feed forming grinding equipment and other specialized machine tools. Widely used in the automotive industry, engineering machinery, intelligent communication, optics, medical, electronics, home appliances, automation equipment, energy, environmental protection, mold manufacturing, general machinery manufacturing, aerospace, shipbuilding, precision machining, medical equipment manufacturing and other industries.