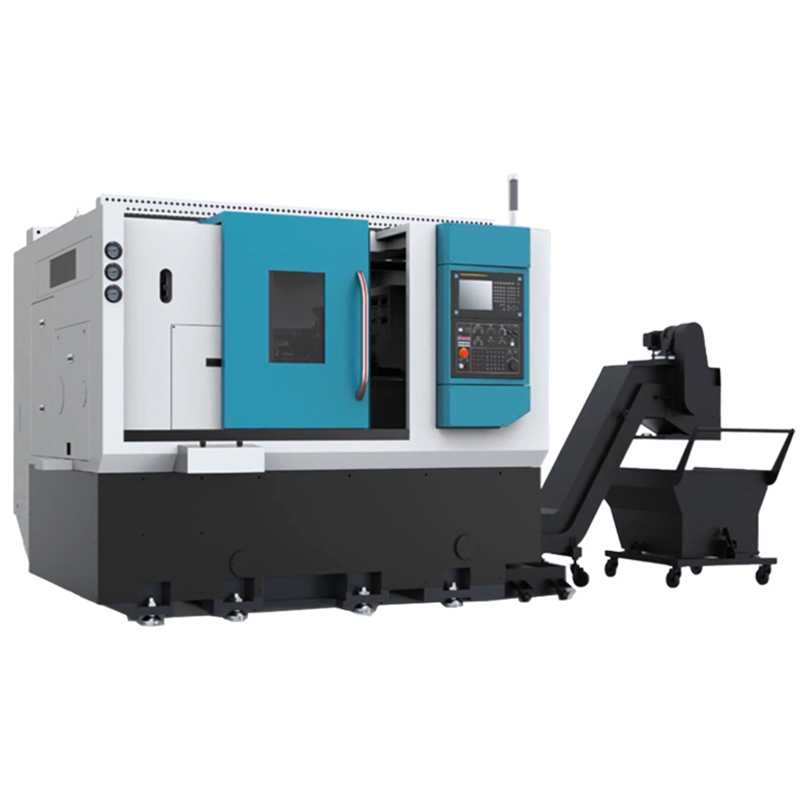

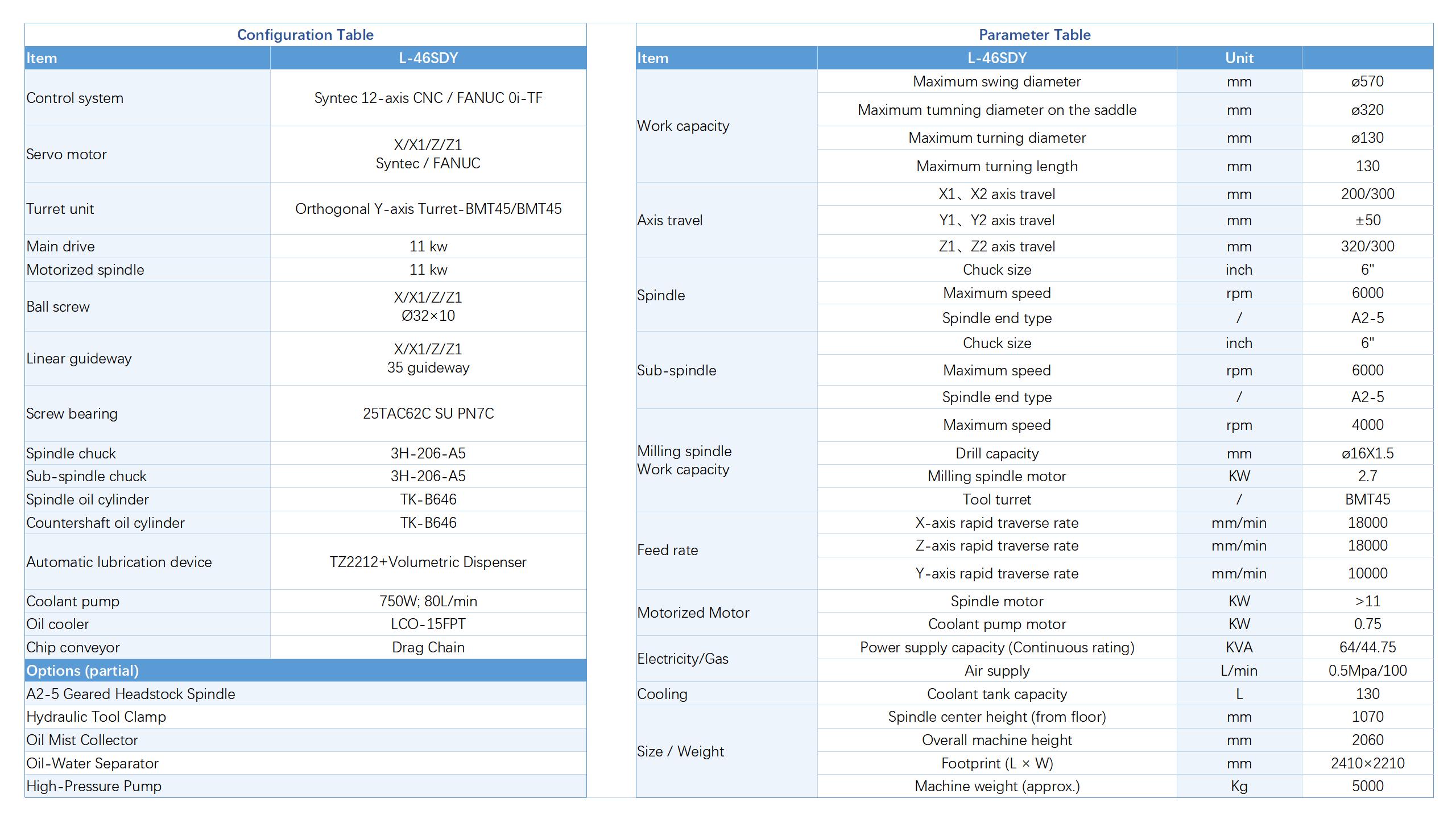

L-46SDY Horizontal Twin Spindle Twin Turret CNC Turning-Milling Center — a high-precision, high-performance turning-milling compound machine engineered for efficient batch production of precision hardware, shaft components, and complex non‑standard parts. | SPECIFICATIONS: √ Twin Spindle Synchronized Machining– enables automated loading and unloading √ Dual Y-Axis Turret Design– equipped with 12 station BMT45 servo tool holder √ Maximum Machining Diameter Φ570mm, Maximum Turning Length 130mm √ Complete machining operations—including turning, milling, drilling, and other processes—in a single setup.

The L-46SDY Twin-Spindle Twin-Turret CNC Lathe represents advanced turning-milling technology for precision manufacturing. Featuring a fully integrated modular design with synchronized dual spindles and dual Y-axis turrets, this CNC turning center delivers complete two-sided machining in a single setup—including turning, milling, drilling, boring, tapping, and engraving. Engineered for high-efficiency production, it is ideal for precision hardware, shaft parts, and complex non-standard components, with automated loading/unloading systems that maximize throughput and accuracy in batch manufacturing applications.

The L-46SDY twin spindle twin turret CNC machining center redefines manufacturing efficiency with its fully integrated design. By combining dual-spindle synchronized transfer and 3D motion dual Y-axis turrets, this CNC turning-milling machine consolidates multiple standalone operations from turning and milling to drilling, boring, and tapping into a single, continuous workflow.

Unlike traditional multi-machine processes, the L-46SDY eliminates inefficiencies, setup repetition, and production bottlenecks, transforming your shop floor from fragmented process flow into seamless process integration. This all-in-one horizontal machining center delivers complete part finishing in one chucking, enabling true single-machine workshop capability for batch production of precision components.

Beyond speed and accuracy, the L-46SDY provides a system-level production upgrade: predictable lead times, consistent part quality, and flexible capacity for complex, non-standard orders—making it the ideal complete machining solution for manufacturers of shafts, precision hardware, and custom engineered parts.

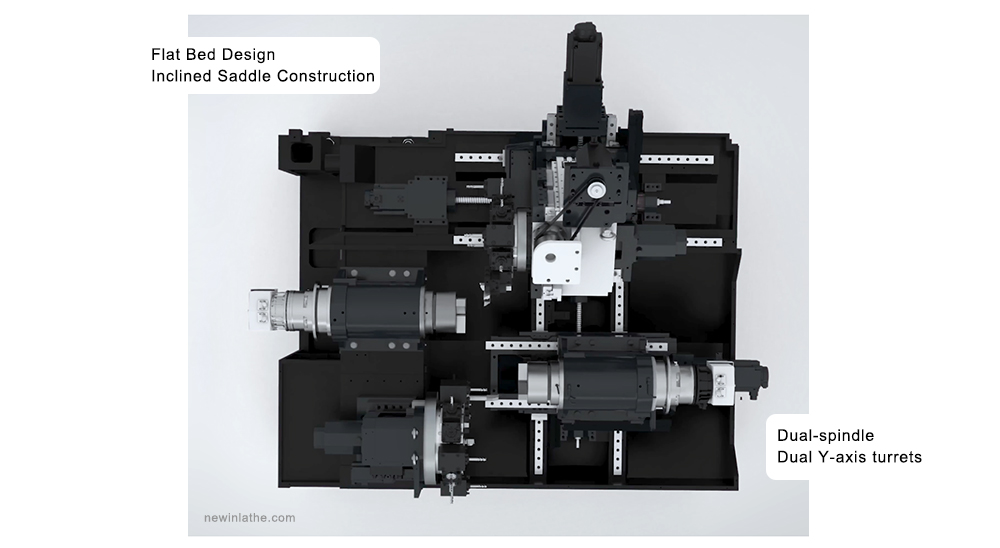

L-46SDY Turning-Milling Center is a high-precision, robust, and versatile machine tool platform. Its main structure features an integral flat bed and inclined saddle design, providing exceptional rigidity and dynamic stability under heavy cutting conditions. Configured with dual spindles, dual turrets, and dual control channels, the machine operates through a full closed-loop control system with precision linear encoders. This ensures high positioning accuracy and reliable repeatability for critical applications.

The synergy between its rigid mechanical foundation and advanced multi-channel control enables flexible integration of various power tools and turning attachments. This allows for complete machining operations—including turning, milling, drilling, and other processes—in a single setup, significantly enhancing production efficiency and process capability for complex components.

Dual spindles enable automated loading/unloading for enhanced machining efficiency.

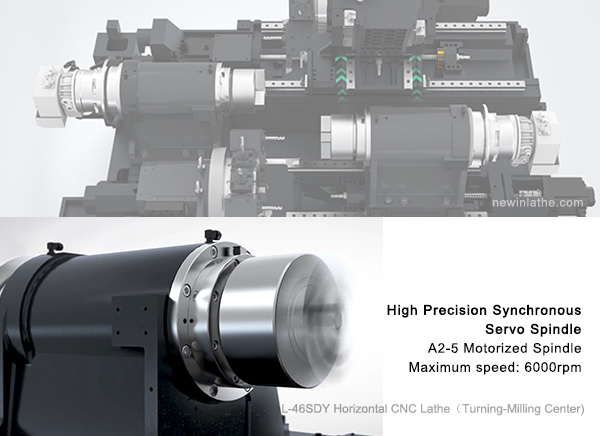

| High Precision Synchronous Servo Spindle (maximum speed-6000rpm) | |

|---|---|

| • The spindle-bed interface employs a paired scraping process to maximize contact rigidity. • With its large span symmetrical structure design, this spindle achieves minimal thermal displacement and consistent long term accuracy in continous operation. • The integrated motorized spindle design provides a more compact structure, with a monobloc housing assembly that delivers enhanced overall rigidity and stability. |  |

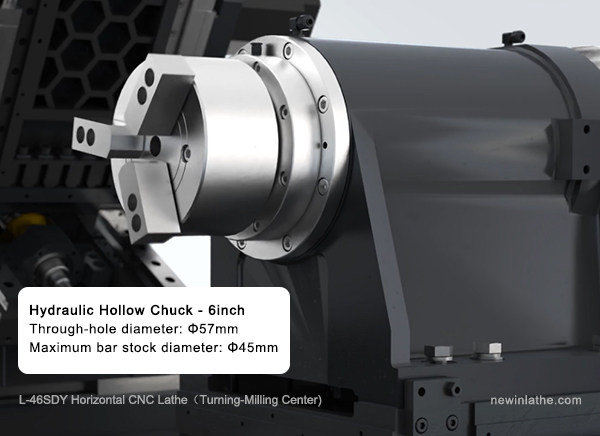

| 6-inch hydraulic three-jaw hollow chuck: Through-hole diameter: Φ57mm, Maximum bar stock diameter: Φ45mm. Featuring central through-tool coolant capability for improved operational convenience. |

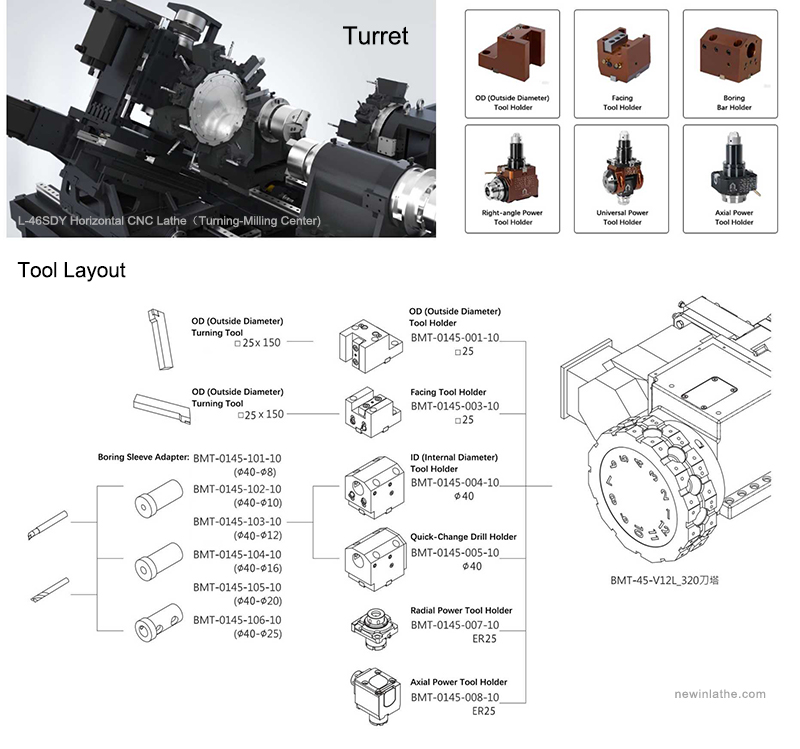

| • Efficient Configuration: Dual servo-powered turrets, each equipped with a 12-station BMT45 servo tool holder. • Structural Advantage: Integrated orthogonal Y-axis structure with high-rigidity design, delivering superior heavy-duty cutting performance compared to interpolated Y-axis systems. • Core Technology: Hydraulic clamping with arc tooth disc precise positioning, combined with servo-driven mechanism for high-speed, high-precision tool changing. • Reliability Assurance: Oil-air lubrication on the milling shaft minimizes heat buildup during extended operation, preventing thermal expansion that could compromise machining precision. |  |

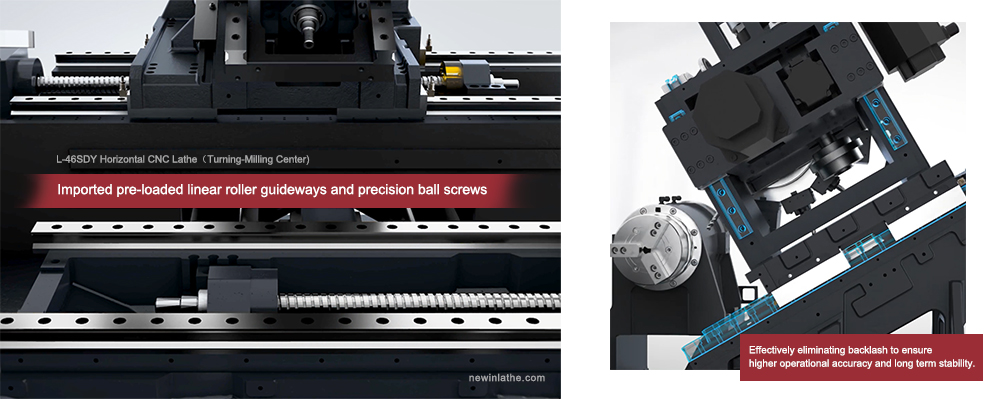

Features imported pre-loaded linear roller guideways and precision ball screws, effectively eliminating backlash to ensure higher operational accuracy and long term stability.

Ball Screw Configuration: Utilizes imported large diameter, high speed, low noise ball screws. An optimal pre-tension design effectively prevents thermal deformation and enhances positioning accuracy.

Guideway Configuration: Equipped with imported heavy-duty roller guideways. They offer excellent rigidity, effectively suppress vibration, extend tool life, provide high precision, fast response, and feature a long service life, meeting customers' demands for long term, reliable operation.

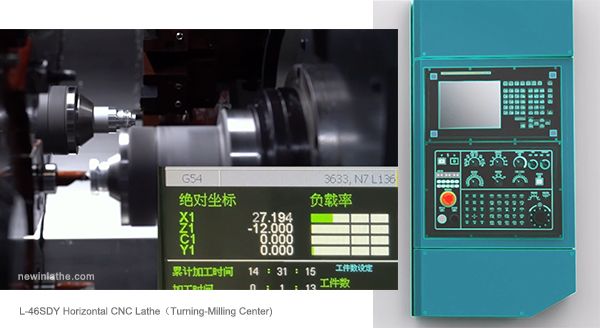

| • Equipped with a Syntec (Taiwan) 12-axis CNC system. • Offers comprehensive CNC machining functions and professional auxiliary capabilities, supporting complex process programming and efficient production management. |  |

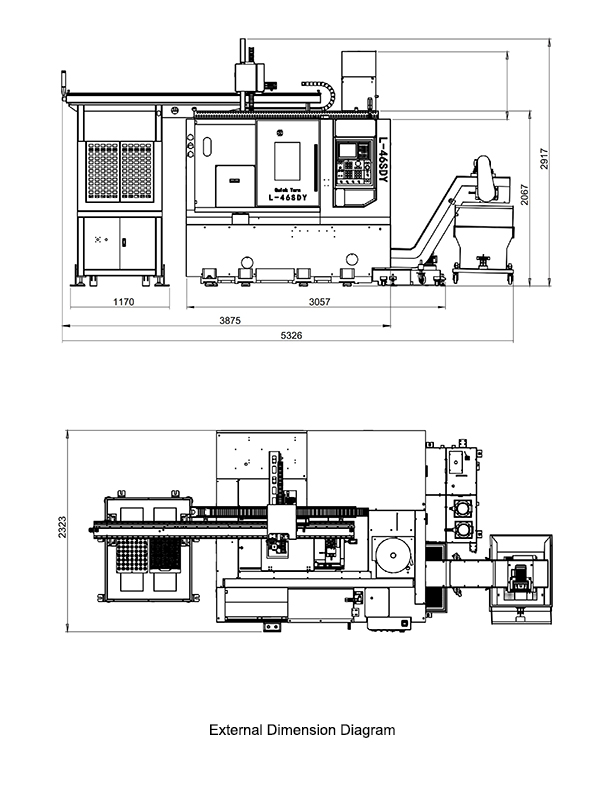

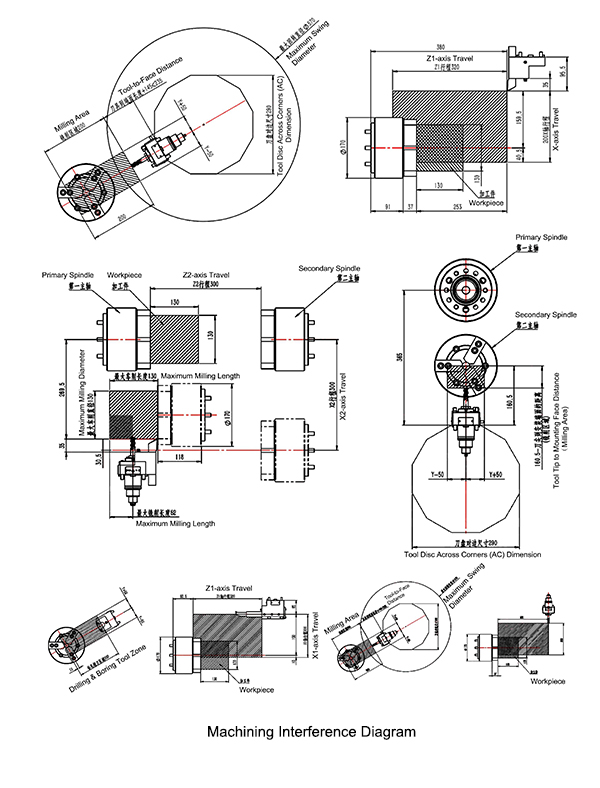

| External Dimension Diagram | Machining Interference Diagram |

|---|---|

|  |

| • Precision Hardware Machining: Connectors, Valve Components, Precision Bushings/Sleeves | • Automotive Components: Transmission Shafts, Steering Parts, Engine Components |

| • Electronics & Electrical: Heat Sinks, Connectors, Precision Housings/Enclosures | • Medical Devices: Surgical Instrument Parts, Implant Components |

| • Aerospace: Small Precision Structural Parts, Connecting Components |

| Control System

| Control System