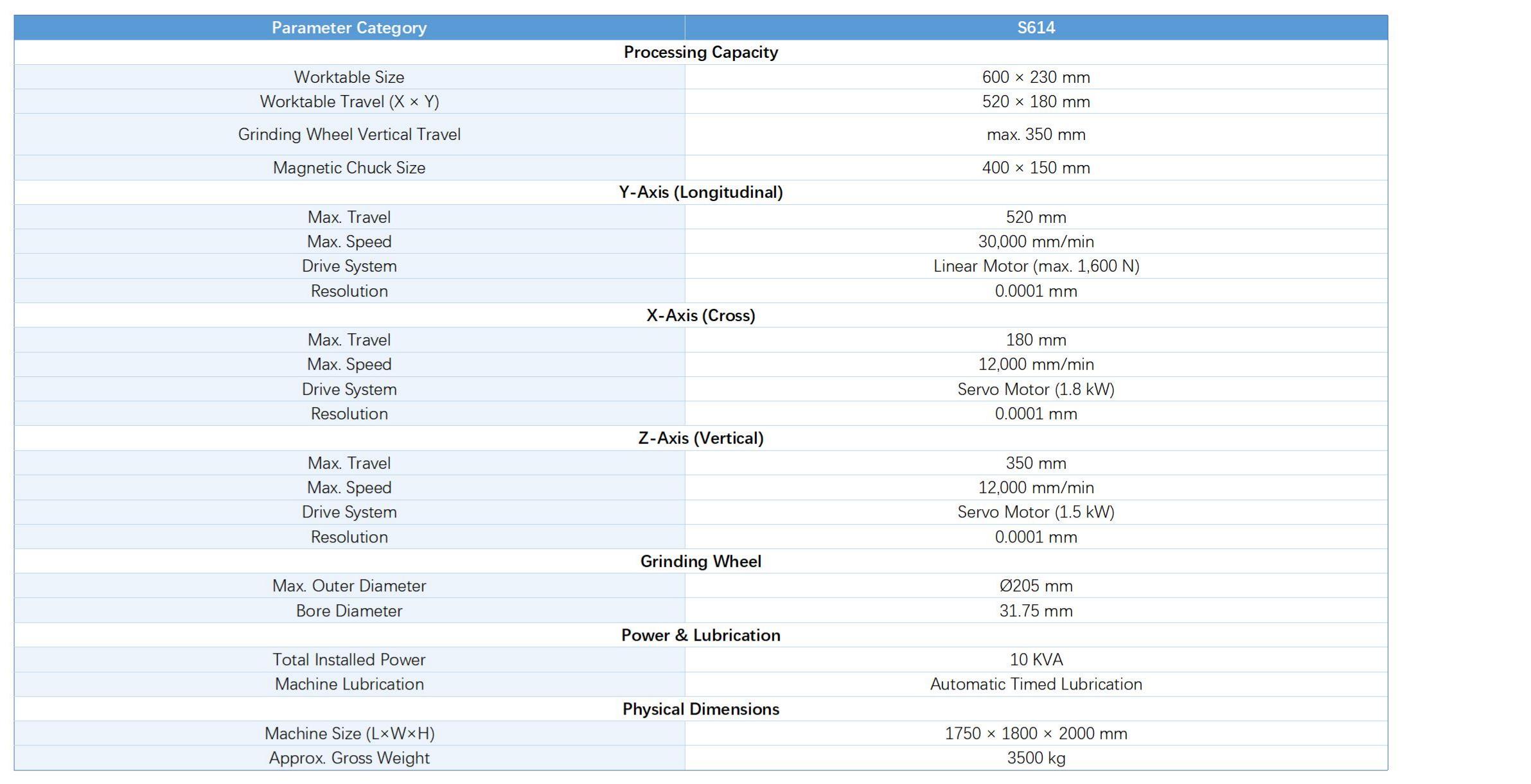

The S614 Ultra-Precision Form Surface Grinding Machine integrates linear motors, interchangeable spindles & CCD inspection for high-precision surface, profile & contour grinding. Ideal for punches, molds & complex parts. | SPECIFICATIONS: √ Ultra-precision, plane/contour/curved surface profile grinding √ Table size: 150*355mm √ Maximum table travel (Y-axis): 400mm √ Maximum table travel (X-axis): 160mm √ Maximum table travel (Z-axis): 350mm √ Y/X/Z axis resolution: 0.0001mm

The S614 Ultra-Precision Form Surface Grinding Machine is a state-of-the-art grinding center engineered for the high-precision and efficient production of complex components like punches, molds, and cutting tools. Equipped with a high-speed linear motor, interchangeable spindles, and an integrated CCD camera inspection system, this advanced machine delivers high accuracy and automation.

As a true multi-function grinding machine, the S614 excels not only in precision surface grinding, profile grinding, and contour grinding but also enables combined milling and drilling operations—all within a single setup. This capability makes it an ideal solution for complex part machining, drastically reducing production time while ensuring exceptional form accuracy.

Its intelligent automation, including rapid tool change systems and intuitive graphical programming, streamlines workflow and minimizes setup times. Whether for precision punch grinding, mold component finishing, or prototyping complex contours, the S614 series offers a comprehensive manufacturing solution.

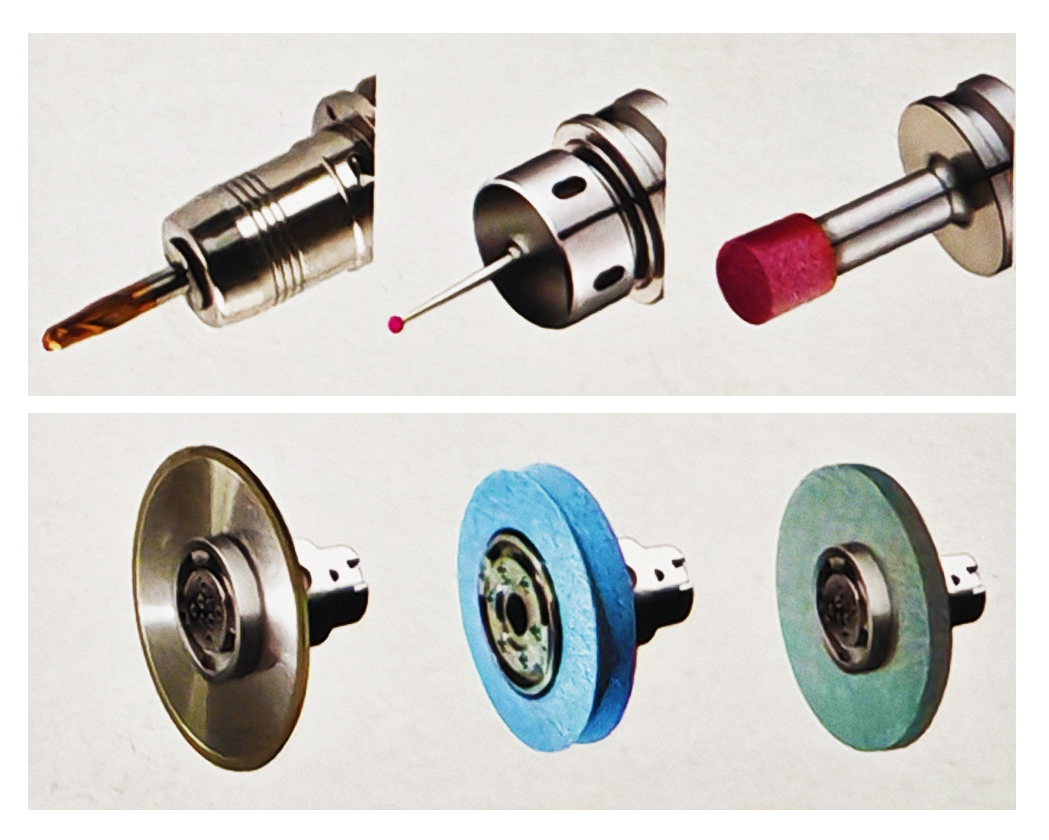

| Linear Motor with Encoder Utilizes a inear motor paired with a high-resolution linear encoder to achieve high-speed, high-precision positioning. | Interchangeable Spindles Supports up to 4 different spindle types (e.g., 30,000 rpm HSK electric spindle) to accommodate various processes such as grinding, milling, and drilling. | Flexible Loading & Process Adaptability • Intelligent Multi-Tool Loading System: Features a high-capacity automatic grinding wheel magazine with a fast tool change device, significantly reducing setup time. It supports flexible configuration of various tools including grinding wheels, dressing wheels, and milling cutters. The system handles combined processes from rough to finish grinding and light milling, enabling multi-operation machining of complex parts in one clamping.  • Multi-Process Attachment Support: Integrates a rotary wheel dressing unit, a dedicated step grinding attachment, and worktable tilt adjustment (front/rear). This expands machining capabilities for high-precision contours, multi-level stepped surfaces, and multi-angle punches, enhancing the machine's process coverage and task adaptability. |  |

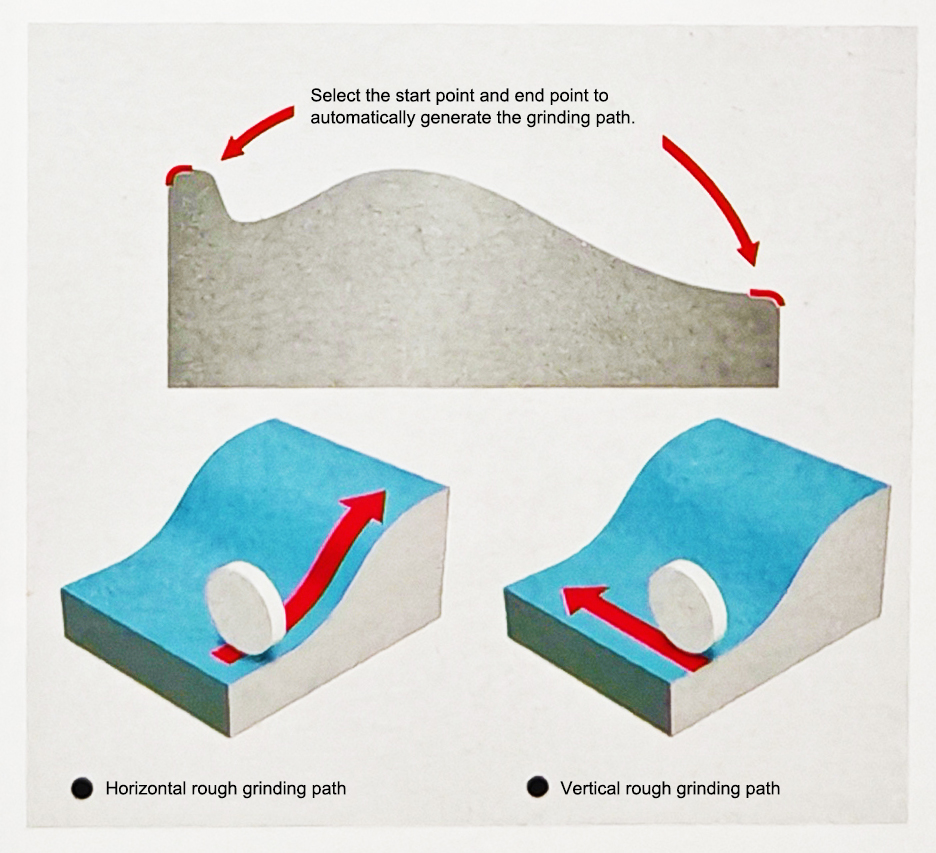

| Smart Interaction & Rapid Programming: Equipped with an intuitive large touch screen and graphical programming interface. Operators only need to set start and end points to automatically generate grinding paths, greatly lowering the skill barrier and programming time. |  |

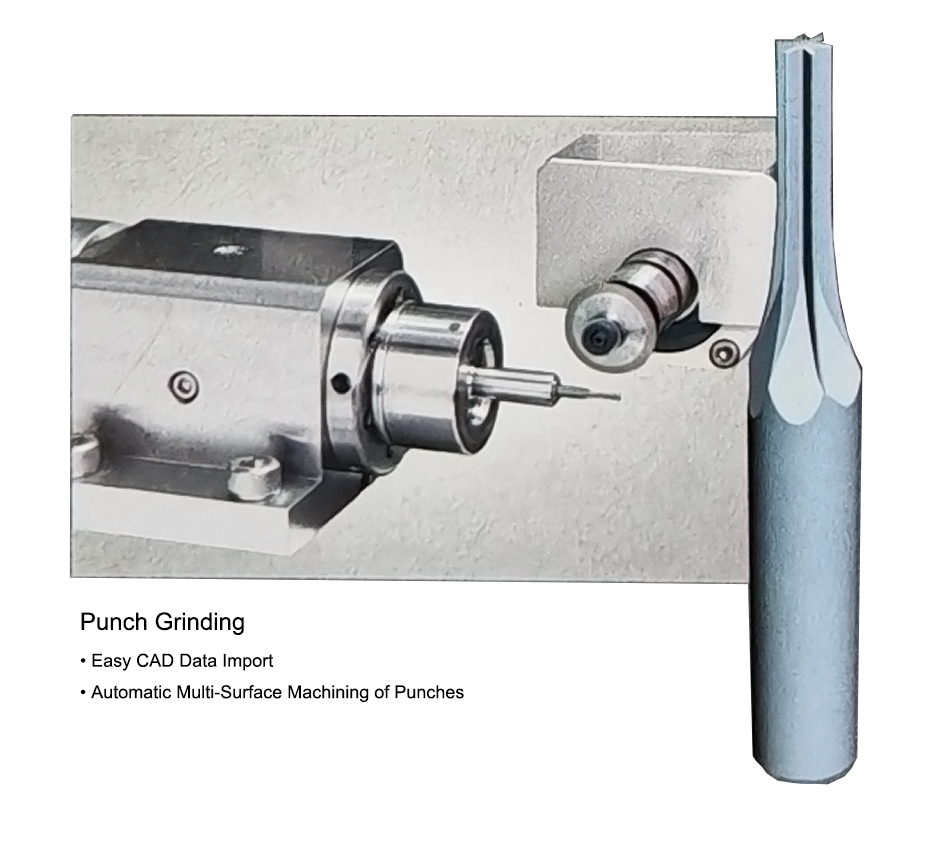

| Integrated CAD Data Processing: Supports direct and easy CAD data import. The system automatically analyzes the model and generates machining programs, ideal for automated processing of complex multi-surface parts like punches. |

| CCD Camera Inspection System: Incorporates a high-precision CCD camera and real-time image processing for on-machine contour measurement and dimensional inspection. This closed-loop control system automatically adjusts the machining path based on feedback, significantly enhancing the digitization and automation of micro-grinding and ensuring superior form accuracy and consistency. |  |

| • Precision Punch Grinding: Supports automatic multi-surface grinding and contour forming. | • Mold Components: High-precision grinding of mold inserts, guide pins, sliders, etc. | • Cutting Tool Manufacturing: Profile and edge grinding of end mills, drills, and form tools. |

| • Precision Mechanical Parts: Complex contour parts for aerospace, medical devices, and electronic components. | • R&D and Prototyping: Suitable for small-batch, high-variety, high-precision requirements in research and trial production scenarios. |

Contact us for detailed configurations or custom grinding solutions.

Contact us for detailed configurations or custom grinding solutions.